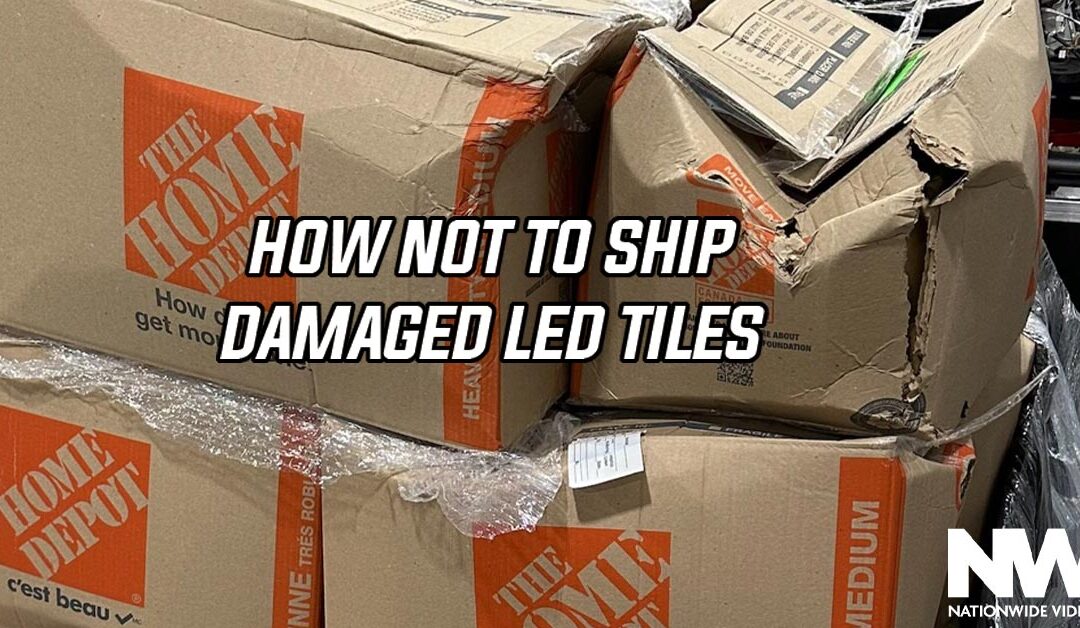

HOW NOT TO SHIP DAMAGED LED TILES

LED tiles are incredibly fragile as is. Risk of damage is just something that you sign up for upon purchase. When tiles get damaged in the field, the silver lining is that they can be repaired. It’s very important to recognize that once damage is sustained by the tile, they should still be treated as precious cargo as they make their way to repair. To ensure that your LED tiles arrive at their destination in perfect condition, it’s important to follow the right packaging and shipping procedures.

Orientation Matters

One of the most common mistakes when packing LED tiles is improper orientation. You should always avoid shipping them face to back. Instead, opt for a “back to back” or “front to front” configuration with a protective barrier in between. This simple step can prevent the tiles from rubbing against each other during transit, minimizing the risk of damage.

Choose the Right Box

Selecting the appropriate box is essential when shipping LED tiles. It must be strong and sturdy enough to support the weight of the modules going inside. Remember that LED tiles can vary in size and weight, so you might need different box sizes for various projects. A heavy-duty, corrugated cardboard box is often a suitable choice, providing the necessary structural support and protection during transportation.

Wrap Modules in Bubble Wrap

To provide an extra layer of protection, wrap the LED modules in bubble wrap. Just because modules are damaged doesn’t mean that they should be left susceptible to sustaining more damage in shipping. Bubble wrap serves as a cushion against shocks and vibrations, reducing the chances of any damage during handling or transit. Be sure to wrap each module individually to ensure maximum protection.

Secure the Modules Inside the Box

Once the LED modules are wrapped in bubble wrap, arrange them inside the box carefully. Make sure they fit snugly without excessive movement. You can use packing materials like foam inserts or additional bubble wrap to fill any gaps and keep the modules in place. The goal is to minimize any internal movement during transit. While the photo below shows the right intention, each tile should be individually wrapped so that there is no room for them to shift during transportation.

Addressing the Challenge of Large Modules

When dealing with larger LED tiles, such as 500 x 250 modules, finding suitable packaging solutions can be a challenge. Currently, there might not be readily available options designed specifically for these dimensions. In such cases, consider custom packaging solutions or consult with packaging experts who can tailor a solution to meet your needs. This extra effort is crucial to safeguarding your initial investment in LED tiles.

Label Fragile Items

Clearly mark the box as containing fragile items. This will alert handlers and carriers to exercise extra care when handling the package. Use “Fragile” stickers or labels and consider using arrows to indicate the proper orientation of the box.

Now What?

Indicating Damaged Pixels

To indicate damage, customers like to mark the bad pixels with Gaff tape. While indicating the damage location is very helpful, the Gaff tape is so sticky that it pulls pixels out when removed. Conversely, painter’s tape is great for marking dead pixels with. It won’t pull out pixels.

Repair

So now that you know how to safely package your damaged LED tiles, where do you send them? Nationwide Repair is the LED repair arm of Nationwide 360. Our team is full of experienced technicians who can get your tiles back in action quickly with some of the shortest turnaround times in the industry. To get started on your LED Repair, contact Nationwide Repair at 800.935.2323 or repairs@nationwidevideo.com.